Retour

Site global

10" Inline Vaneaxial Fan, 120V, 1~

Numéro article: 56067

Ce ventilateur de conduit multifonctionnel à haut rendement déplace de grands volumes d'air avec une faible consommation d'énergie. Idéal pour les longs conduits de ventilation dans les environnements à faible pression statique.

• Taux d'efficacité élevé (pcm/W)

La forme optimisée de la turbine aérodynamique permet d'obtenir un flux d'air idéal. Les roulements du moteur sont scellés de façon permanente et auto-lubrifiés pour une durée de vie sans entretien. Le moteur étant dans le courant d'air, le ventilateur assure la dissipation constante de la chaleur accumulée, ce qui confère à ce ventilateur une longévité et une fiabilité exceptionnelles, couvertes par notre garantie imbattable dans le secteur.

Les exemples d'applications générales du ventilateur prioAIR comprennent les systèmes de conduits d'air d'alimentation ou d'évacuation dans les bâtiments commerciaux, les écoles, les gymnases, les salles de bains commerciales, les installations de fabrication avec des conduits étendus, les garages résidentiels attenants, les besoins de renforcement des conduits extra-longs et les vides sanitaires.

| Données nominales | ||

|---|---|---|

| Tension (nominale) | 115 | V |

| Fréquence | 60 | Hz |

| Phases | 1~ | |

| Puissance installée | 308 | W |

| Intensité | 2.59 | A |

| Vitesse de rotation | 2 976 | tr/min |

| Débit d'air | max 651 | L/s |

| Température air en mouvement | max 55 | °C |

| Temp. max. avec variateur | 55 | °C |

| Protection/Classification | ||

|---|---|---|

| Classe d'étanchéité, moteur | IP44 | |

| Classe d'isolation | F |

| Dimensions et Poids | ||

|---|---|---|

| Conduit Circul d'aspiration | 10 | po. |

| Conduit Circul de refoulement | 10 | po. |

| Poids | 13.7 | lb |

| Option | ||

|---|---|---|

| Type de connexion | Circulaire | |

| Couleur, enveloppe | Noir | |

| Type de moteur | AC | |

| Material | Plastique |

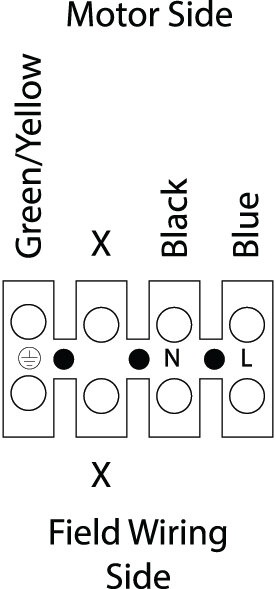

| Factory Motor Wiring (For reference only) | Terminal Marking | Field Marking (to be completed by installer) |

Color |

Function |

|

Blue |

L |

Power supply 120VAC, 50/60 Hz |

Black |

N |

Neutral conductor |

Green/Yellow |

PE |

Protective conductor |

| Tableau de pi3/min | ||||||||

Modèle |

0.0" Ps |

0.2" Ps |

0.4" Ps |

0.6" Ps |

0.8" Ps |

1.0" Ps |

1.5" Ps |

2.0" Ps |

prioAir 6 |

295 |

252 |

195 |

38 |

- |

- |

- |

- |

prioAir 8 |

646 |

606 |

553 |

487 |

300 |

160 |

- |

- |

prioAir 10 |

1380 |

1324 |

1264 |

1200 |

1127 |

1043 |

546 |

37 |

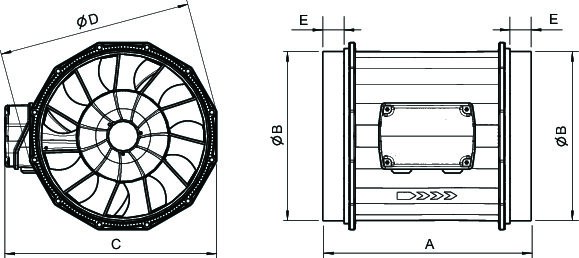

| A | B | C | D | E | |

prioAir 8/ 8EC |

9 11/16 (246) |

7 7/8 (200) |

9 3/4 (248) |

9 (229) |

1 (25) |

prioAir 10/ 10EC |

11 11/16 (297) |

9 13/16 (249) |

11 15/16 (303) |

11 1/16 (281) |

1 3/16 (30) |

Dimensions en pouces (mm). |

|||||

GUIDE SPECIFICATION

Specifier Notes: This guide specification is written in Construction Specifications Institute (CSI) 3-Part Format in accordance with The CSI Construction Specifications Practice Guide, MasterFormat, SectionFormat, and PageFormat.

Specifier Notes: This Section must be carefully reviewed and edited by the Architect or Engineer to meet the requirements of the Project and local building code. Coordinate this Section with Division 01, other specification sections, and the Drawings. Delete all Specifier Notes after editing this Section.

Section numbers and titles are based on MasterFormat 2014 Update.

SECTION 23 34 00

HVAC FANS

Specifier Notes: This Section covers Fantech prioAir Series circular inline duct fans with alternating current (AC) motors. Consult Fantech for assistance in editing this Section as required for the Project.

PART 1. GENERAL

1.1 SECTION INCLUDES

A. Circular inline duct fans with alternating current (AC) motors.

1.2 RELATED REQUIREMENTS

Specifier Notes: Edit the following list of related sections as required for the Project. Limit the list to sections with specific information that the reader might expect to find in this Section, but is specified elsewhere.

A. Section 23 31 00 – HVAC Ducts and Casings.

B. Section 26 05 00 – Common Work Results for Electrical.

1.3 REFERENCE STANDARDS

Specifier Notes: List reference standards used elsewhere in this Section, complete with designations and titles. Delete reference standards from the following list not used in the edited Section.

A. Air Movement and Control Association International (AMCA) (www.amca.org):

1. AMCA 211 – Certified Ratings Program - Product Rating Manual for Fan Air Performance.

2. AMCA 311 – Certified Sound Ratings Program for Air Moving Devices.

B. Underwriting Laboratory (UL) (https://productiq.ulprospector.com/en):

1. UL 507- Electric Fans

2. UL 705- Power Roof Ventilators

3. CSA 22.2 No 113- Fans and Ventilators

1.4 PREINSTALLATION MEETINGS

Specifier Notes: Edit the Preinstallation Meetings article as required for the Project. Delete article if not required.

A. Convene preinstallation meeting [1 week] [2 weeks] before start of Work of this Section.

B. Require attendance of parties directly affecting Work of this Section, including Contractor, Architect, installer, and manufacturer’s representative.

C. Review the Following:

1. Materials

2. Installation

3. Adjusting

4. Protection

5. Coordination with other Work

1.5 SUBMITTALS

Specifier Notes: Edit the Submittals article as required for the Project. Delete submittals not required.

A. Comply with Division 01.

B. Product Data: Submit manufacturer’s product data, including installation instructions.

C. Shop Drawings: Submit manufacturer’s shop drawings, including plans, elevations, sections, and details.

1. Wiring Diagrams: Indicate wiring for each item of equipment and interconnections between items of equipment.

2. Include manufacturer’s names, model numbers, ratings, power requirements, equipment layout, device arrangement, complete wiring point-to-point diagrams, and conduit layouts.

D. Manufacturer’s Certification: Submit manufacturer’s certification that materials comply with specified requirements and are suitable for intended application.

E. Operation and Maintenance Data:

1. Submit manufacturer’s operation and maintenance manual; including the following:

a. Operation, maintenance, adjustment, and cleaning instructions.

b. Troubleshooting guide

c. Parts list

d. Electrical wiring diagrams if required.

2. Provide detailed information required for Owner to properly operate and maintain equipment.

F. Warranty Documentation: Submit manufacturer’s standard warranty.

1.6 QUALITY ASSURANCE

A. Manufacturer’s Qualifications: Manufacturer regularly engaged in the manufacturing of circular inline duct fans to that specified for a minimum of 10 years.

B. Installer's Qualifications:

1. Installer regularly engaged in installation of circular inline duct fans of similar type to that specified for a minimum of 5 years.

2. Use persons trained for installation of circular inline duct fans.

1.7 DELIVERY, STORAGE, AND HANDLING

A. Delivery Requirements: Deliver materials to site in manufacturer’s original, unopened containers and packaging, with labels clearly identifying product name and manufacturer.

B. Storage and Handling Requirements:

1. Store and handle materials in accordance with manufacturer’s instructions.

2. Keep materials in manufacturer’s original, unopened containers and packaging until installation.

3. Store materials in clean, dry area indoors.

4. Keep materials from freezing.

5. Protect materials during storage, handling, and installation to prevent damage.

1.8 WARRANTY

Warranty Period: 5 years

PART 2. PRODUCTS

2.1 MANUFACTURERS

A. Manufacturer: Fantech Inc., 10048 Industrial Blvd., Lenexa, Kansas 66215. Phone 800-747-6217. www.fantech.net. ussupport@fantech.net.

Specifier Notes: Specify if substitutions will be permitted.

B. Substitutions: [Not permitted] [Comply with Division 01].

C. Single Source: Provide materials from single manufacturer.

2.2 HVAC FANS

A. Circular inline Duct Fans with alternating current (AC) motors: prioAir Series

1. AMCA Air & Sound Seal

2. CULus Listed

Specifier Notes: Specify circular inline duct fan models as required for the Project. Delete models not required.

A. Model: “prioAir 6”

1. Inlet Diameter: 5-7/8 inches

2. Outlet Diameter: 5-7/8 inches

3. Casing Diameter: 7-3/8 inches

4. Inlet and Outlet Connection Collars: 1-5/8 inch

5. Casing Material: Composite. A housing seam joined with screws or rivets is unacceptable.

6. Motor: Alternating current external-rotor motor

7. Impeller: axial impellers and guide vanes

8. Speed Control: by altering supply voltage via an external stepless controller

9. Motor Protection: electronically protected

10. Voltage: 120 V

11. Frequency: 50/60 Hz

12. Nominal Voltage Range: 100 to 130 V

13. Phase: 1

14. Maximum Airflow: 295 cfm

15. RPM: 2,754

16. Power Rating, Motor: 37 W

17. Current: 0.31 A

18. Operational Temperature: minus 13 to 131 degrees F

19. Weight: 3.3 lbs

20. Motor Insulation Class: B

21. Motor Enclosure Class: IP44

B. Model: “prioAir 8”

1. Inlet Diameter: 7-7/8 inches

2. Outlet Diameter: 7-7/8 inches

3. Casing Diameter: 9 inches

4. Inlet and Outlet Connection Collars: 1 inch

5. Casing Material: Composite. A housing seam joined with screws or rivets is unacceptable.

6. Motor: Alternating current external-rotor motor

7. Impeller: axial impellers and guide vanes

8. Speed Control: by altering supply voltage via an external stepless controller

9. Motor Protection: electronically protected

10. Voltage: 120 V

11. Frequency: 50/60 Hz

12. Nominal Voltage Range: 100 to 130 V

13. Phase: 1

14. Maximum Airflow: 646 cfm

15. RPM: 2,899

16. Power Rating, Motor: 96 W

17. Current: 0.8 A

18. Operational Temperature: minus 13 to 131 degrees F

19. Weight: 7.5 lbs

20. Motor Insulation Class: B

21. Motor Enclosure Class: IP44

C. Model: “prioAir 10”

1. Inlet Diameter: 9-13/16 inches

2. Outlet Diameter: 9-13/16 inches

3. Casing Diameter: 11-1/16 inches

4. Inlet and Outlet Connection Collars: 1-3/16 inch

5. Casing Material: Composite. A housing seam joined with screws or rivets is unacceptable.

6. Motor: Alternating current external-rotor motor

7. Impeller: axial impellers and guide vanes

8. Speed Control: by altering supply voltage via an external stepless controller

9. Motor Protection: electronically protected

10. Voltage: 120 V

11. Frequency: 50/60 Hz

12. Nominal Voltage Range: 100 to 130 V

13. Phase: 1

14. Maximum Airflow: 1,379 cfm

15. RPM: 2,976

16. Power Rating, Motor: 308 W

17. Current: 2.59 A

18. Operational Temperature: minus 13 to 131 degrees F

19. Weight: 13.7 lbs

20. Motor Insulation Class: B

21. Motor Enclosure Class: IP44

2.3 ACCESSORIES

A. Silencers for Circular Ducts

Specifier Notes: Delete accessories not required.

1. Model: [“LD 6”] [“LD 8”] [“LD 10”]

2. Insulation Thickness: 2 inches.

B. Mounting Clamps for Circular Ducts

Specifier Notes: Delete accessories not required.

1. Model: [“FC 6”] [“FC 8”] [“FC 10”]

2. Material: Galvanized sheet metal with 1/3 inch neoprene lining

3. Width: 2-1/3 inches

4. Clamps Together: 2 screws

5. Quantity: 2 pcs per kit

C. External Remotely Mounted Speed Controller

Specifier Notes: Delete if not required.

1. Model: WC15

2. Remotely mounted manual-speed control for air flow adjustments and balancing.

3. Voltage: 120V

4. Amperage: 5A max

5. Enclosure class: IP54

D. Inlet Safety Guard

Specifier Notes: Delete if not required.

1. Model: [“IG 4”] [“IG 5”] [“IG 6”] [“IG 8”] [“IG 10”] [“IG 12”]

2. Wire ring inlet guard prevents foreign objects from entering inline duct fan Zinc chromate plated steel.

PART 3. EXECUTION

3.1 EXAMINATION

A. Examine areas to receive circular inline duct fans.

B. Notify Architect of conditions that would adversely affect installation or subsequent use.

C. Do not begin installation until unacceptable conditions are corrected.

3.2 INSTALLATION

A. Install circular inline duct fans in accordance with manufacturer’s instructions at locations indicated on the Drawings.

B. Attach duct work to inlet and outlet connection collars of circular inline duct fans in accordance with manufacturer’s instructions.

C. Electrical: Install electrical power to circular inline duct fans as specified in Section 26 05 00.

3.3 ADJUSTING

A. Adjust circular inline duct fans for proper operation in accordance with manufacturer’s instructions.

3.4 PROTECTION

A. Protect installed circular inline duct fans from damage during construction.

END OF SECTION

| Nom du document | Type de document | |

|---|---|---|

| E1839 prioAir FR | Brochure | |

| 484065 prioAir OIPM.PDF | Manuel |

Contrôle de vitesse, ac interrupteur marche-arrêt 120V, 5A

10" Capot métal fixe pr Approvisionnement/Air d’échappement

10" Clapet de surpression pr conduit circulaire, simple

conduits circulaires 10", isolation 2", joints en caoutchouc