Dryer Exhaust Duct Power Ventilator, listed to UL705

Item #: 499195

This product is a dryer exhaust duct power ventilator (DEDPV). It complies with UL 705: Safety Power Ventilators and is suitable for gas and electric dryers.

• Supports duct runs up to 125 linear feet

The DEDPV-705 is a cord connected product that features a pressure switch to automatically sense when the dryer is on. A wall-mounted indicator panel with a 50-foot cable is provided to indicate proper operation of the exhaust fan.

This product helps your dryer run more efficiently by overcoming pressure losses caused by long or restricting exhaust duct designs and/or from the effects of high altitudes. The DEDPV can help your dryer achieve a higher exhaust rate to produce faster drying times.

Four FC 4 Mounting Clamps (#411295) and two cleanouts come with the product to ease installation of the product on the ductwork. An integrated thermal fuse is built into the DEDPV-705 as a safety device and will de-energize the product in the event of abnormal exhaust temperatures.

Performance certified by HVI, and safety certified by UL to the DEDPV supplement of UL705.

Some helpful tips for installing the DEDPV 705:

• Do not use rigid PVC pipes or flexible ducts. Use only steel or aluminum ducts rated for dryer use. These ducts have smooth walls, so lint is less likely to build up.

| Nominal data | ||

|---|---|---|

| Voltage (nominal) | 120 | V |

| Voltage type | AC | |

| Frequency | 60 | Hz |

| Phases | 1~ | |

| Input power | 78 | W |

| Input current | 0.58 | A |

| Impeller speed | 2,600 | rpm |

| Air flow | max 168 | cfm |

| Temperature of transported air | max 167 | °F |

| Protection/Classification | ||

|---|---|---|

| Enclosure class, motor | IP44 | |

| Insulation class | B | |

| Certificate | HVI, UL to the DEDPV supplement to UL705, UL to CSA C22.2 No. 113 |

| Dimensions and weights | ||

|---|---|---|

| Duct dimension; Circular, inlet | 4 | in. |

| Duct dimension; Circular, inlet | 4 | in. |

| Duct dimension; Circular, outlet | 4 | in. |

| Weight | 13.3 | lb |

| Optional | ||

|---|---|---|

| Duct connection type | Circular | |

| Motor type | AC | |

| Altitude | 0 to 10,000 | ft |

| Material | Metal |

| Elevation | Max. Eq. Duct Length (ft.) |

Sea Level |

125 |

2,000 |

114 |

4,000 |

106 |

6,000 |

98 |

8,000 |

92 |

10,000 |

85 |

12,000 |

80 |

| HVI Certified Rating(s) | ||

Static Pressure (In. Wg.) |

Rated Airflow (CFM) |

Rated Power (Watts) |

0.20" |

150 |

78 |

|

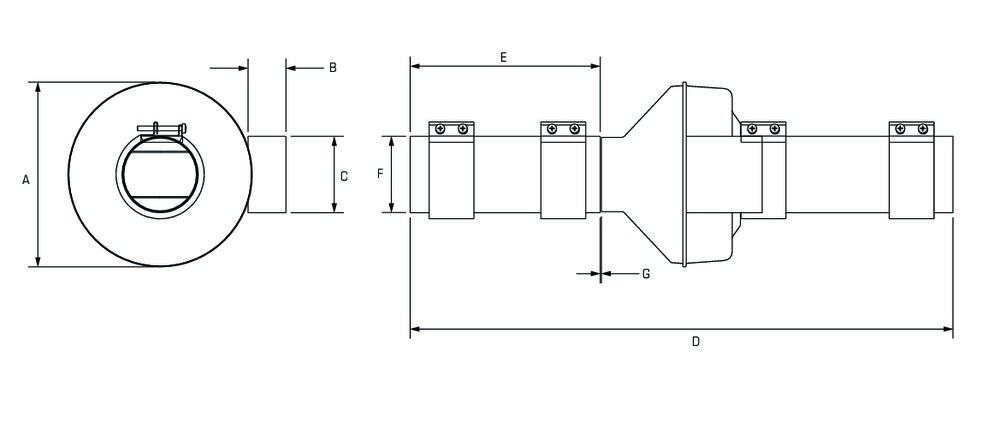

A | B | C | D | E | F | G | |||||||

DEDPV-705 |

9 11/16 |

2 |

4 |

28 9/16 |

10 |

4 |

1/32 |

|||||||

Dimensions are in inches |

||||||||||||||

GUIDE SPECIFICATION

Specifier Notes: This guide specification is written in Construction Specifications Institute (CSI) 3-Part Format in accordance with The CSI Construction Specifications Practice Guide, MasterFormat, SectionFormat, and PageFormat.

Specifier Notes: This Section must be carefully reviewed and edited by the Architect or Engineer to meet the requirements of the Project and local building code. Coordinate this Section with Division 01, other specification sections, and the Drawings. Delete all Specifier Notes after editing this Section.

Section numbers and titles are based on MasterFormat 2014 Update.

SECTION 23 34 00

HVAC FANS

Specifier Notes: This Section covers Fantech “DEDPV-705” dryer exhaust duct power ventilator. Consult Fantech for assistance in editing this Section as required for the Project.

Specifier Notes: Use of DEDPV-705 dryer exhaust duct power ventilator complies with the UL standard related to dryer exhaust (the DEDPV supplement of UL705) and is suitable for gas and electric clothes dryers. Consult Fantech for more information.

PART 1. GENERAL

1.1 SECTION INCLUDES

A. Dryer Exhaust Duct Power Ventilators

1. DEDPV-705

1.2 RELATED REQUIREMENTS

Specifier Notes: Edit the following list of related sections as required for the Project. Limit the list to sections with specific information that the reader might expect to find in this Section, but is specified elsewhere.

A. Section 23 31 00 – HVAC Ducts and Casings.

B. Section 26 05 00 – Common Work Results for Electrical.

1.3 PREINSTALLATION MEETINGS

Specifier Notes: Edit the Preinstallation Meetings article as required for the Project. Delete article if not required.

A. Convene preinstallation meeting [1 week] [2 weeks] before start of Work of this Section.

B. Require attendance of parties directly affecting Work of this Section, including Contractor, Architect, installer, and manufacturer’s representative.

C. Review the Following:

1. Materials

2. Installation

3. Adjusting

4. Protection

5. Coordination with other Work

1.4 SUBMITTALS

Specifier Notes: Edit the Submittals article as required for the Project. Delete submittals not required.

A. Comply with Division 01.

B. Product Data: Submit manufacturer’s product data, including installation instructions.

C. Shop Drawings: Submit manufacturer’s shop drawings, including plans, elevations, sections, and details.

1. Wiring Diagrams: Indicate wiring for each item of equipment and interconnections between items of equipment.

2. Include manufacturer’s names, model numbers, ratings, power requirements, equipment layout, device arrangement, complete wiring point-to-point diagrams, and conduit layouts.

D. Manufacturer’s Certification: Submit manufacturer’s certification that materials comply with specified requirements and are suitable for intended application.

E. Operation and Maintenance Data:

1. Submit manufacturer’s operation and maintenance manual; including the following:

a. Operation, maintenance, adjustment, and cleaning instructions.

b. Troubleshooting guide

c. Parts list

d. Electrical wiring diagrams if required.

2. Provide detailed information required for Owner to properly operate and maintain equipment.

F. Warranty Documentation: Submit manufacturer’s standard warranty.

1.5 QUALITY ASSURANCE

A. Manufacturer’s Qualifications: Manufacturer regularly engaged in the manufacturing of dryer exhaust duct power ventilators to that specified for a minimum of 5 years.

B. Installer's Qualifications:

1. Installer regularly engaged in installation of circular inline duct fans of similar type to that specified for a minimum of 5 years.

2. Use persons trained for installation of circular inline duct fans.

1.6 DELIVERY, STORAGE, AND HANDLING

A. Delivery Requirements: Deliver materials to site in manufacturer’s original, unopened containers and packaging, with labels clearly identifying product name and manufacturer.

B. Storage and Handling Requirements:

1. Store and handle materials in accordance with manufacturer’s instructions.

2. Keep materials in manufacturer’s original, unopened containers and packaging until installation.

3. Store materials in clean, dry area indoors.

4. Keep materials from freezing.

5. Protect materials during storage, handling, and installation to prevent damage.

1.7 WARRANTY

Warranty Period: 5 years

PART 2. PRODUCTS

2.1 MANUFACTURERS

A. Manufacturer: Fantech Inc., 10048 Industrial Blvd., Lenexa, Kansas 66215. Phone 800-747-6217. www.fantech.net. ussupport@fantech.net.

Specifier Notes: Specify if substitutions will be permitted.

B. Substitutions: [Not permitted] [Comply with Division 01].

C. Single Source: Provide materials from single manufacturer.

2.2 HVAC FANS

A. Dryer Exhaust Duct Power Ventilator (DEDPV-705)

1. Listed to the DEDPV supplement of UL705

Specifier Notes: Specify circular inline duct fan models as required for the Project. Delete models not required.

B. Model: “DEDPV-705”.

1. Inlet Diameter: 4 inches.

2. Outlet Diameter: 4 inches.

3. Casing Diameter: 9-11/16 inches.

4. Inlet and Outlet Connection Collars: 1 inch.

5. Casing Material: Galvanized Metal with air-tight, folded seam construction. A housing seam joined with screws or rivets is unacceptable.

6. Motors: External-rotor AC motor.

7. Integral pressure switch for altitude range of 0-10,000 ft above sea level

8. Motor Protection: Thermal overload protection with automatic reset.

9. Air Temperature Limit Safety Cutoff: Integral thermal fuse

10. Voltage: 120 V.

11. Frequency: 50/60 Hz.

12. Nominal Voltage Range: 100 to 130 V.

13. Phase: 1.

14. Maximum Airflow: 161 cfm.

15. RPM: 2,601

16. Power Rating, Motors: 69 W.

17. Current: 0.58 A.

18. Operational Temperature: max 167 degrees F.

19. Weight: 13.3 lbs.

20. Motor Insulation Class: B.

21. Motor Enclosure Class: IP44.

2.3 ACCESSORIES

A. Secondary lint trap

1. Model: “DBLT4W”

2. Inlet Diameter: 4 inches

3. Outlet Diameter: 4 inches

4. Weight: 2.3 lbs.

B. External Louver Exhaust:

1. Model: “HS4W”.

2. Plastic louvered shutter with duct connection

3. Inlet Diameter: 4 inches

4. Exterior Dimension: 6 inches x 6 Inches

5. Length: 11 inches.

PART 3. EXECUTION

3.1 EXAMINATION

A. Examine areas to receive a dryer exhaust duct power ventilator.

B. Notify Architect of conditions that would adversely affect installation or subsequent use.

C. Do not begin installation until unacceptable conditions are corrected.

3.2 INSTALLATION

A. Install dryer exhaust duct power ventilators in accordance with manufacturer’s instructions at locations indicated on the Drawings.

B. Attach duct work to inlet and outlet connection collars of dryer exhaust duct power ventilators in accordance with manufacturer’s instructions.

C. Electrical: Install electrical power to dryer exhaust duct power ventilators fans as specified in Section 26 05 00.

3.3 ADJUSTING

A. Adjust dryer exhaust duct power ventilators for proper operation in accordance with manufacturer’s instructions.

3.4 PROTECTION

A. Protect installed dryer exhaust duct power ventilators from damage during construction.

END OF SECTION

| Document file name | Document file type | |

|---|---|---|

| 411958 DEDPV White paper Fantech EN.pdf | Brochure | |

| 450608 DEDPV-705 Submittal Sheet EN.pdf | Brochure | |

| Case Study Chicago Resident Dryer Fire | Brochure | |

| E1939 Ventilation Solutions Laundries | Brochure | |

| 483443 DEDPV IOM EN | Manual | |

| 48344319 DEDPV-705 IOM ES | Manual | |

| UL Certification of Compliance - E165879 | Certificate |