Side duct connection HRV, 1428 cfm

Item #: 99274

| Unit | ||

|---|---|---|

| Frequency | 60 | Hz |

| Voltage (nominal) | 120 | V |

| Phases | 1~ | |

| Input current | 10.6 | A |

| MCA | 14.25 | A |

| MOP | 15 | A |

| Input power | 1 272 | W |

| Air flow | max 674 | L/s |

| Nominal max static pressure (in. w.g.) | 100 | Pa |

| Others | ||

|---|---|---|

| Installation type | Horizontal |

| Dimensions and weights | ||

|---|---|---|

| Weight | 235.9 | lb |

| Certificates | ||

|---|---|---|

| Certificate | CSA, AHRI 1060 Components |

Supply Temperature |

Net Airflow |

Sensible net effectiveness |

Total net effectiveness |

|

°F (°C) |

cfm (L/s) |

% |

% |

|

Heating |

35 (1.7) |

1410 (665) |

52 |

34 |

35 (1.7) |

1058 (499) |

54 |

36 |

|

Cooling |

95 (35) |

1410 (665) |

52 |

20 |

95 (35) |

1058 (499) |

54 |

21 |

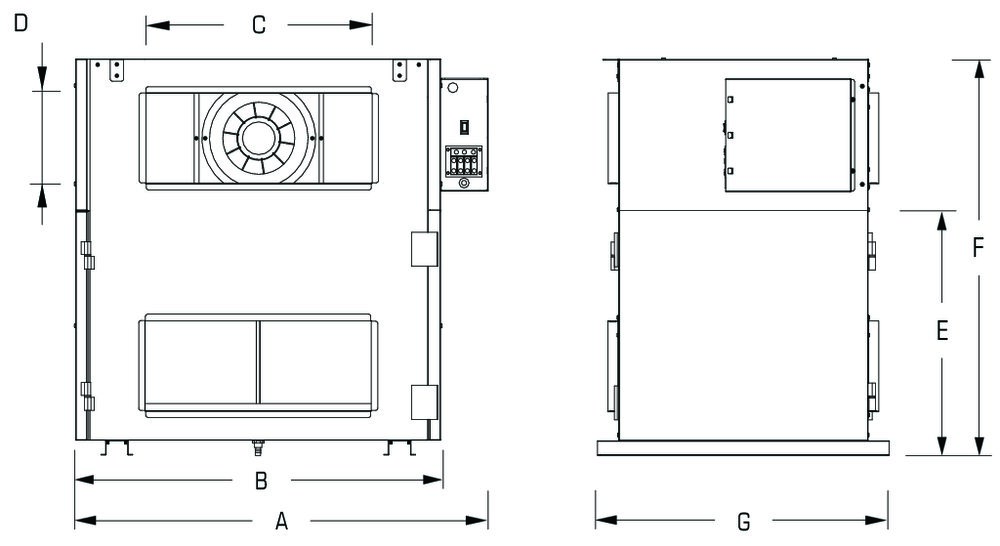

| A | B | C | D | E | F | G | Drain Spout |

51 2/5 (1306) |

47 1/5 (1199) |

24 (610) |

8 (203) |

21 1/2 (546) |

35 (889) |

25 3/4 (654) |

1/2 (13) |

GUIDE SPECIFICATION

Specifier Notes: This guide specification is written in Construction Specifications Institute (CSI) 3-Part Format in accordance with The CSI Construction Specifications Practice Guide, MasterFormat, SectionFormat, and PageFormat.

Specifier Notes: This Section must be carefully reviewed and edited by the Architect or Engineer to meet the requirements of the Project and local building code. Coordinate this Section with Division 01, other specification sections, and the Drawings. Delete all Specifier Notes after editing this Section.

Section numbers and titles are based on MasterFormat 2016 Update.

SECTION 23 72 15

Specifier Notes: This Section covers Fantech’s SHR Series of Heat Recovery Ventilators. Consult Fantech for assistance in editing this Section as required for the Project.

PART 1. GENERAL

1.1 SECTION INCLUDES

A. Heat Recovery Ventilators

1.2 RELATED REQUIREMENTS

Specifier Notes: Edit the following list of related sections as required for the Project. Limit the list to sections with specific information that the reader might expect to find in this Section, but is specified elsewhere.

A.Section 23 08 00 – Commissioning of HVAC

1.3 REFERENCE STANDARDS

Specifier Notes: List reference standards used elsewhere in this Section, complete with designations and titles. Delete reference standards from the following list not used in the edited Section.

A. ANSI/AHRI 1060 Components– Performance Rating of Air-to-Air Heat Exchangers for Energy Recovery Ventilation Components.

B. ANSI/AMCA 300 – Reverberant Room Method for Sound Testing of Fans.

C. ASHRAE 84 – Method of Testing Air-to-Air Heat Exchangers.

D. ASTM A 792/A 792M – Standard Specification for Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by the Hot-Dip Process.

E. CSA C22.2, No. 77 – Motors with Inherent Overheating Protection.

F. CSA C22.2, No. 100 – Motors and Generators.

G. CSA C22.2, No. 113 – Fans and Ventilators.

H. CSA C22.2, No. 236 – Heating and Cooling Equipment.

I. ISO 9001:2015 – Quality Management Systems – Requirements.

J. NFPA 70 – National Electrical Code (NEC).

K. UL 723 – Standard for Test for Surface Burning Characteristics of Building Materials.

L. UL 900 – Standard for Air Filter Units.

M. UL 1004-2 – Standard for Impedance Protected Motors.

N. UL 1004-3 – Standard for Thermally Protected Motors.

O. UL 1004-7 – Standard for Electronically Protected Motors.

P. UL 1812 – Standard for Ducted Heat Recovery Ventilators.

Q. UL 2111 – Standard for Overheating Protection for Motors.

1.4 PREINSTALLATION MEETINGS

Specifier Notes: Edit the Preinstallation Meetings article as required for the Project. Delete article if not required.

A. Convene preinstallation meeting [1 week] [2 weeks] before start of Work of this Section.

B. Require attendance of parties directly affecting Work of this Section, including Contractor, Architect, installer, and manufacturer’s representative.

C.Review the Following:

1.Materials

2.Installation

3.Adjusting

4.Protection

5.Coordination with other Work

1.5 SUBMITTALS

Specifier Notes: Edit the Submittals article as required for the Project. Delete submittals not required.

A. Comply with Division 01.

B. Product Data: Submit manufacturer’s product data, including installation instructions.

C. Shop Drawings: Submit manufacturer’s shop drawings, including plans, elevations, sections, and details.

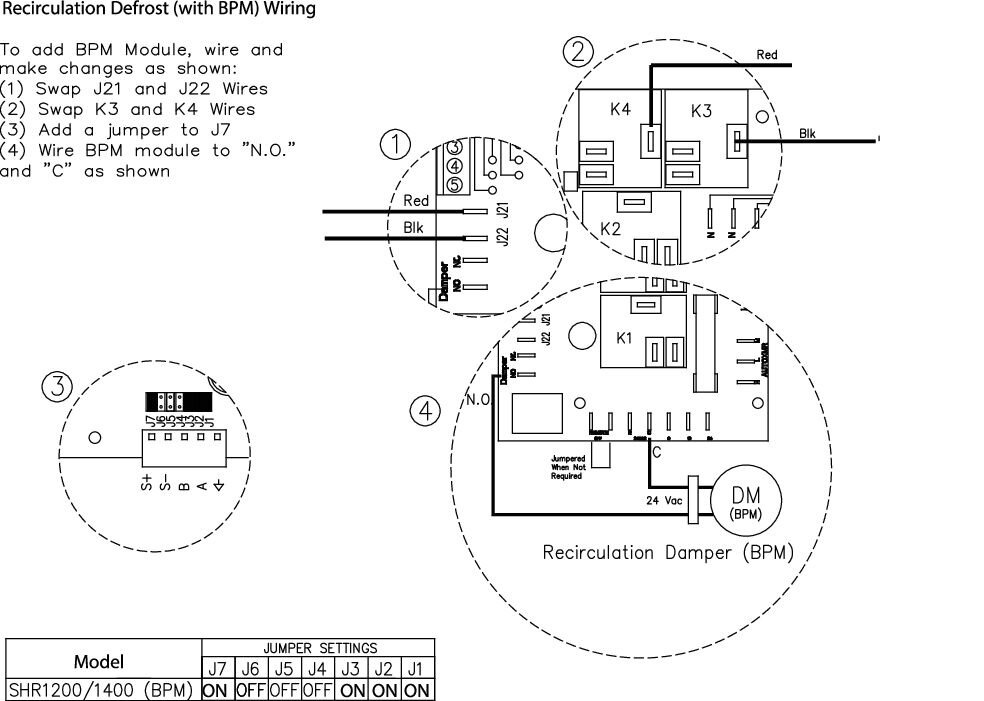

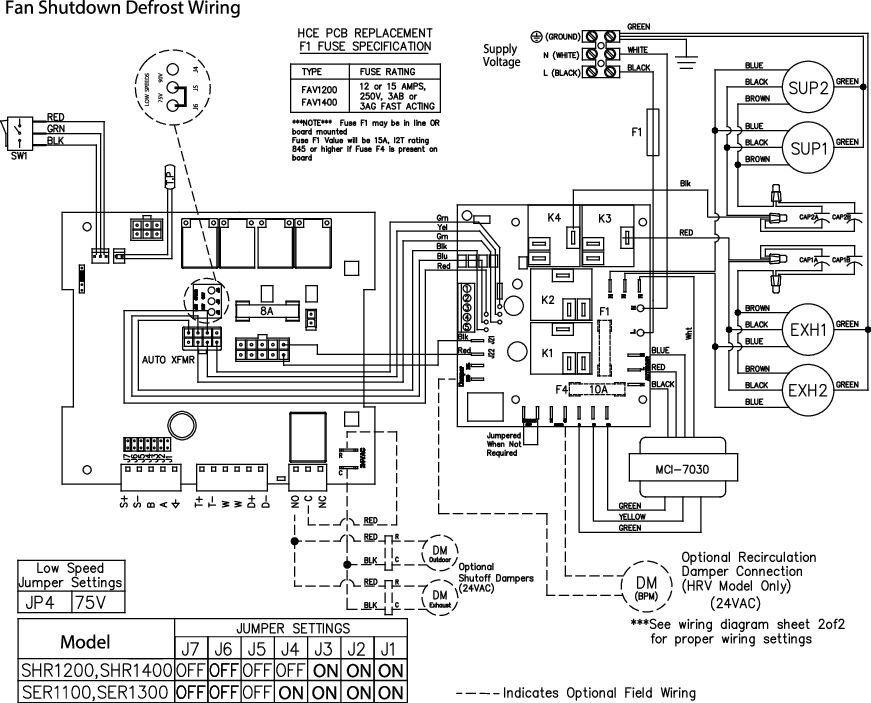

1. Wiring Diagrams: Indicate wiring for each item of equipment and interconnections between items of equipment.

2. Include manufacturer’s names, model numbers, ratings, power requirements, equipment layout, device arrangement, complete wiring point-to-point diagrams, and conduit layouts.

D. Manufacturer’s Certification: Submit manufacturer’s certification that materials comply with specified requirements and are suitable for intended application.

E. Operation and Maintenance Data:

1.Submit manufacturer’s operation and maintenance manual; including the following:

a. Operation, maintenance, adjustment, and cleaning instructions.

b. Troubleshooting guide

c. Parts list

d. Electrical wiring diagrams if required.

2. Provide detailed information required for Owner to properly operate and maintain equipment.

F. Warranty Documentation: Submit manufacturer’s standard warranty.

1.6 QUALITY ASSURANCE

A. Manufacturer’s Qualifications:

1. Manufacturer regularly engaged in the manufacturing of air handling units, heat or energy recovery ventilators in the last 10 years.

2. ISO 9001 Certified

B. Installer's Qualifications:

1. Installer regularly engaged in installation of air handling units, heat or energy recovery ventilators to that specified for a minimum of 5 years.

2. Use persons trained for installation of air handling units, hear or energy recovery ventilators

1.7 DELIVERY, STORAGE, AND HANDLING

A. Delivery Requirements: Deliver materials to site in manufacturer’s original, unopened containers and packaging, with labels clearly identifying product name and manufacturer.

B. Storage and Handling Requirements:

1. Store and handle materials in accordance with manufacturer’s instructions.

2. Keep materials in manufacturer’s original, unopened containers and packaging until installation.

3. Store materials in clean, dry area indoors.

4. Keep materials from freezing.

5. Protect materials during storage, handling, and installation to prevent damage.

1.8 WARRANTY

Warranty Period: 3 years

PART 2. PRODUCTS

2.1 MANUFACTURERS

A. Manufacturer: Fantech Inc., 50 Kanalflakt Way, Bouctouche, New Brunswick E4S 3M5, Canada. For Canada: Toll Free 800-565-3548, CANADAsupport@fantech.net

For USA: Toll Free 800-747-1762, USsupport@fantech.net

Specifier Notes: Specify if substitutions will be permitted.

B.Substitutions: [Not permitted] [Comply with Division 01].

C.Single Source: Provide materials from single manufacturer.

2.2 HEAT RECOVERY VENTILATORS

A. Heat Recovery Ventilators: SHR Series

1. Models: SHR450, SHR700, SHR800, SHR1200, SHR1400

2. Indoor, compact, light-commercial heat recovery ventilators.

Specifier Notes: Specify required model. Consult Fantech for assistance in determining heat recovery ventilator model for the specific application.

B. General

1. Each Unit or Group of Units: Capable of operating in any mode independently or dependently of other systems.

2. Capable of changing modes with no interruption to system operation.

3. Listed under CSA C22.2, No. 113-15/UL 1812.

4. Wiring: NFPA 70.

5. Performance: As scheduled on the Drawings.

6. Equip with control systems.

7. Perform all functions necessary for operation.

8. Ventilation to Building: Not to cease in any mode based solely on operational temperature of minus 13 to 104 degrees F (minus 25 to 40 degrees C).

9. Capable of changing modes with no interruption to system operation.

10. Capable of transferring both sensible and latent heat between the fresh and stale air streams.

11. Capable of operating in winter and summer conditions without imbalance or loss of ventilation capacity greater than specified in design.

C. Unit Cabinet

12. Single Wall Cabinet:

a. 22-gauge sheet galvanized steel, G90 coated with lapped corners.

b. Seams: Sealed, requiring no caulking in field.

13. Insulation within a Single Wall:

a. 1.0-inch (25.4-mm) fiberglass.

b. Flame Spread Index, UL 723: Not over 25.

c. Smoke Developed Index, UL 723: Not over 50.

14. Cabinet Doors & Panels

a. 22-gauge G90 pre-painted sheet galvanized steel.

b. 1.0-inch (25.4-mm) fiberglass.

D. Fans

1. Direct-drive, backward-inclined, motorized ECM impellers

2. Fan Motors:

a. Maintenance-free, permanently lubricated, sealed ball bearings.

b. Thermal overload protected (TOP).

c. UL listed to UL1004 and/or UL2111, CSA C22.2 No. 77 and No.100

d. IP Protection: Class 44.

3. Separate fans for exhaust and supply blowers.

E. Heat recovery exchanger

1. Exchanger Construction: Fixed plate cross-flow heat exchanger using 1100 alloy aluminum and capable of transferring sensible heat between air streams. The heat recovery exchanger shall be engineered with a turbulence inducing geometry to maximize heat transfer while allowing an effective evacuation of condensate. The plates shall be hemmed to avoid cross-contamination of airstreams. The flame spread index of the heat recovery core shall not be over 25 and its smoke development index shall not be over 50 when tested in accordance with the Standard for Tests for Surface Burning Characteristics of Building Material, UL723.

2. Cross-flow construction type.

3. Free cooling capacity.

4. Performance: Certified and listed by AHRI Components.

5. Frame Material: Corner profiles in PVC and gables in aluminum-zinc sheet steel

6. Effectiveness of exchanger: Documented in accordance with ASHRAE 84 and AHRI 1060. Components

7. Flame Spread Index, Heat Recovery Exchanger, UL 723: Not over 25.

8. Smoke Developed Index, Heat Recovery Exchanger, UL 723: Not over 50.

F. Air filters

1. Supply and exhaust air protected by MERV3 mesh filters constructed to meet UL 900. (Optional MERV8 or MERV13 filters are direct replacement to the MERV3 in size)

G. Frost control

1. Frost control sequence (pre-set) initiated if the outdoor air temperature falls below the set point of 23°F (-5°C)

H. Electrical 1 Phase Input Voltage

1. Electrical Power: 120 VAC, 1 Phase, 60 Hz, MOP 15A

2. Internal Electrical Components:

a. Factory wired for single-point power connection.

b. UL Listed or Recognized and CSA Certified or Accepted where applicable and wired in compliance with the National Electrical Code.

3. Electrical Box Components: Accessible without stopping unit or opening doors.

4. Electrical Box:

a. Isolated from airflow paths.

b. Protect integral wires and connections.

I. Serviceability

1. Access Panel: Hinged and/or screwed access panel on front of unit.

2. Heat Recovery Exchangers, Filters, and Motors: Serviceable from front of unit.

3. Fan Assemblies: Mounted on removable base.

4. Heat Recovery Exchangers and Filters: Mounted on slide-out rails.

2.3 ACCESSORIES

A. Shutter damper with spring-return actuators for Rectangular Ducts

Specifier Notes: Delete accessories not required.

1. Model: [“EFD 14-8”] [“EFD 20-8”] [“EFD 24-8”]

2. Spring-return actuators: motorized, 24 V motors with spring-return actuators.

3. Leakage: less than 1%

2.4 ASSEMBLY

A. Factory assembled and wired heat recovery ventilators

2.5 SOURSE QUALITY CONTROL

A. Run test at factory

PART 3. EXECUTION

3.1 EXAMINATION

A. Examine areas to receive heat recovery ventilators.

B. Notify Architect of conditions that would adversely affect installation or subsequent use.

C. Do not begin installation until unacceptable conditions are corrected.

3.2 PREPARATION

A. Prepare surfaces where heat recovery ventilators are to be mounted.

B. Ensure surfaces are flat, level, plumb, and can support weight of heat recovery ventilators

3.3 INSTALLATION

A. Install heat recovery ventilators in accordance with manufacturer’s instructions at locations indicated on the Drawings

B. Install heat recovery ventilators in accordance with NFPA 70

C. Install heat recovery ventilators, rod mount or seat on a platform, level, plumb, and secure.

D. Do not expose electronic components to temperatures below 32 degrees F (0 degrees C) or above 122 degrees F (50 degrees C).

3.4 ADJUSTING

A. Adjust heat recovery ventilators for proper operation in accordance with manufacturer’s instructions.

3.5 DEMONSTRATION

A. Demonstration

1. Demonstrate that heat recovery ventilators function properly in every respect

2. Provide hands-on demonstrations of operation of system components and complete system, including user-level program changes and function

3. Provide instruction and training by factory-trained and certified representative of manufacturer

3.6 PROTECTION

A. Protect installed heat recovery ventilators from damage during construction.

END OF SECTION

| Document file name | Document file type | |

|---|---|---|

| E1863 Light Commercial Brochure EN | Brochure | |

| E400045 SHR1400 Submittal Sheet.pdf | Brochure | |

| E400050 SHR 1400 - SER 1300 Dimensional Submittal.pdf | Brochure | |

| 444567 Light Commercial SHR IOM EN FR.pdf | Manual | |

| SHR 1400 with BPM.dxf | CAD-file | |

| SHR 1400, SER 1300.dxf | CAD-file | |

| SHR1400-SER1300 Revit File | CAD-file | |

| 444585 SHR1400 Spec Sheet.pdf | Spec Sheet |

TVOC sensing controller, multi-function, touchscreen,4 wires